Pipe friction can have a significant impact to a pump’s performance – long discharge pump runs (even if they are flat and not a part of the head calculation) should always be calculated when determining the right equipment for the job. If you are asking for our guidance on pump selection, long discharge runs should always be mentioned in that initial call to Hydra-Tech Pumps. Pipe friction reduces flow – here’s an example to walk you through the calculation.

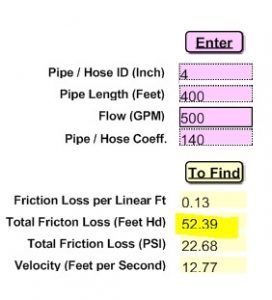

Say you are planning on using an S4THL and an HT35DYS to move some water. The job calls for pumping 500 gallons per minute at a head of 50’. The S4THL’s A curve (based on the hydraulic output available from the HT35DYS) tells you that at 50’ you are right at the 500 gallons per minute mark. However, in addition to the vertical head requirement, you will also be pumping through 400’ of smooth bore 4” ID plastic discharge pipe. We have a tool on our computers that allows us to enter the data necessary to determine what the pipe friction loss will add to the original head number. Below is the calculation where we entered the discharge pipe ID (4”), the length of the discharge hose (400’) the expected flow of the pump based on the 50’ of head already calculated (500 GPM), and the Hazen-Williams Coefficient. The result of the pipe friction loss is 52.39 feet of head, so I add that to my original head of 50 feet for a total of 102.39 feet of head.

Now when I look at my pump curve for this setup, I know that I cannot get any flow with the A curve (shut off head is about 90’) and I will need to use a 74 horsepower hydraulic power unit with a flow of 29 GPM at 2900 PSI to achieve my 500 GPM desired flow. There are situations where moving up a size on the discharge hose can negate the pump friction loss but in this example, the velocity (the speed of the pumped water moving through the discharge hose) is too low and if there are solids in what is being pumped, the velocity of the water could cause a problem.

A quick internet search can yield not only the mathematical formula to allow you to add this calculation to your arsenal of pump tools, but will also allow you to find the complete Hazen-Williams chart, basically a standard set of numbers rating types of pipe / hose / water conveyance against one another. The lower the number, the poorer the choice / means of conveyance (for example 40 year old cast iron pipe is have and has a very low coefficient and fiberglass pipe is excellent and has a very high coefficient). There are also apps for your phone that put the formula within reach. We are always happy to do the math for you as well.