Pumps are mechanical devices used to move a liquid from one place to another. On the most basic level, without allowing for friction losses, the difference in altitude from place A to place B is called the pump head requirement. It is measured in linear units such as feet or meters. The flow of the pump is measured in volumes per unit time, such liters per minute or US gallons per minute. The pump curve shows the relationship between these two measurements.

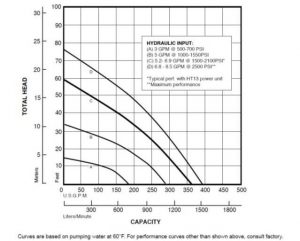

Here is an example of a curve and how to interpret it.

Head– height of liquid column is on the y-axis or vertical axis

We calculate feet of head to see how much pressure (psi=feet of head /2.31) the pump must overcome to deliver the resulting output flow at the delivery point.

Capacity– volume of liquid, is on the x-axis or horizontal axis

**Make sure you take notice to the unit of measure each one is being measured in. **

This point is showing this particular pump can supply 210 GPM @ 45 feet of head

You will notice each line is labeled from A-D, this is showing the different hydraulic inputs needed to make the pump run at the different levels of efficiency.

For example, in order to get your pump to pump 75 GPM @ 50 feet of head you would need a hydraulic unit able to provide 6 GPM @ 1500-2100 PSI, which you can find at Hydra-Tech Pumps with their HT13G portable hydraulic power unit.

*The maximum shutoff head (where all flow stops) of this pump is 75 feet. The best efficiency point of the pump would be about 85% of the maximum shutoff head. So at 64 feet the pump would be running most efficiently.