https://conta.cc/3H4auaG

Happy Earth Day! Green Efforts – Part 1

Environmental responsibility is something that Hydra-Tech Pumps is always working on, even when it isn’t Earth Day. From the offices to the manufacturing floor and machine shop, we are constantly looking at our processes and waste stream to see what we can do to reduce our impact on the environment. In our 2021 newsletters, we will publish three segments on our efforts in April, August and December highlighting our efforts. Here are some of the things Hydra-Tech Pumps does on a regular basis to protect the environment:

- Since moving the business to Nesquehoning in 2007, we have always recycled our paper, cardboard, aluminum, glass and plastic. This is actually a cost to the company as we have a single stream dumpster on site that allows us to properly dispose of these kinds of items for reuse as recycled content in new products.

- We recycle the ink cartridges from all of our printers.

- Paperless punch clock and paperless payroll.

- We recycle steel, aluminum, stainless steel and other materials that are a byproduct of our in house machining of parts. Thousands of pounds of metals are recycled by Hydra-Tech Pumps every year.

Doing the right thing isn’t always cheap and it isn’t always easy. However we believe in leaving a place better than we found it so we are diligent about recycling and properly dealing with the waste stream generated by our business. Look for details on more of our green efforts in the August newsletter.

Green Efforts – Part 2

On Earth Day in April, we began a three part segment in our 2021 newsletters talking about environmental stewardship and what Hydra-Tech Pumps contributes to these efforts. Environmental responsibility is something that Hydra-Tech Pumps is always working on. From the offices to the manufacturing floor and machine shop, we are constantly looking at our processes and waste stream to see what we can do to reduce our impact on the environment. Here are some of the things Hydra-Tech Pumps does on a regular basis to protect the environment:

- We properly dispose of glass waste generated by our blasting process. Using crushed glass in our process instead of sand is actually safer for our employees as well.

- We have replaced 70% of the old tube style fluorescent lighting in our manufacturing space with energy saving LED lighting. The fluorescent tubes are being returned for proper disposal and the old fixtures are in some cases being recycled / repurposed. We will replace all of the fixtures as time and resources allow.

- In the new 8000 square foot addition to our plant, we have high efficiency heaters to warm the space as well as low energy / high efficiency lighting in place.

- We recycle all of the cardboard boxes that come into our facility (as well as the packing materials in the boxes). Most boxes are shredded to be used as packing materials for our outbound shipments of product to customers. What we don’t shred goes into the single stream dumpster for recycling.

We like to think of ourselves as the character Jeff Goldblum plays in the movie Independence Day. Trying to save the planet one aluminum can at a time.

Green Efforts – Part 3

On Earth Day in April we began a three part segment in our 2021 newsletters talking about environmental stewardship and what Hydra-Tech Pumps contributes to these efforts. We followed up in August with a second segment and will wrap it up here. Environmental responsibility is something that Hydra-Tech Pumps is always working on. From the offices to the manufacturing floor and machine shop, we are constantly looking at our processes and waste stream to see what we can do to reduce our impact on the environment. Here are some of the things Hydra-Tech Pumps does on a regular basis to protect the environment:

- Hydra-Tech Pumps participates annually in an electronics recycling event in Nesquehoning where computers, cables, phones, televisions and other electronic equipment are given to a company that recycles all of the components properly. In 2019 we sponsored our own even where we had Gaylord boxes in our plant that were filled up with electronics and eventually shipped to the same company for recycling and proper disposal.

- Waste oil recycling.

- Hydra-Tech Pumps uses clean propane to heat all of the manufacturing and office space at our facility.

- Pallet and Gaylord recycling. We receive a lot of product from our suppliers on pallets and in Gaylord style boxes. We reuse the majority of the pallets and Gaylord boxes that we receive to protect our customers’ shipments when we send them.

We are doing our part to be minimize our impact on the environment and our environmental liability. Hopefully you are doing your part too!

https://conta.cc/3cJBPlo

https://conta.cc/3D22Nj2

Pipe friction can have a significant impact to a pump’s performance – long discharge pump runs (even if they are flat and not a part of the head calculation) should always be calculated when determining the right equipment for the job. If you are asking for our guidance on pump selection, long discharge runs should always be mentioned in that initial call to Hydra-Tech Pumps. Pipe friction reduces flow – here’s an example to walk you through the calculation.

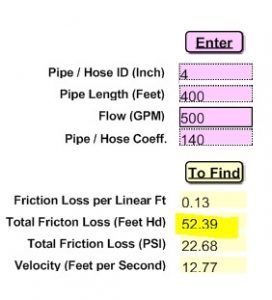

Say you are planning on using an S4THL and an HT35DYS to move some water. The job calls for pumping 500 gallons per minute at a head of 50’. The S4THL’s A curve (based on the hydraulic output available from the HT35DYS) tells you that at 50’ you are right at the 500 gallons per minute mark. However, in addition to the vertical head requirement, you will also be pumping through 400’ of smooth bore 4” ID plastic discharge pipe. We have a tool on our computers that allows us to enter the data necessary to determine what the pipe friction loss will add to the original head number. Below is the calculation where we entered the discharge pipe ID (4”), the length of the discharge hose (400’) the expected flow of the pump based on the 50’ of head already calculated (500 GPM), and the Hazen-Williams Coefficient. The result of the pipe friction loss is 52.39 feet of head, so I add that to my original head of 50 feet for a total of 102.39 feet of head.

Now when I look at my pump curve for this setup, I know that I cannot get any flow with the A curve (shut off head is about 90’) and I will need to use a 74 horsepower hydraulic power unit with a flow of 29 GPM at 2900 PSI to achieve my 500 GPM desired flow. There are situations where moving up a size on the discharge hose can negate the pump friction loss but in this example, the velocity (the speed of the pumped water moving through the discharge hose) is too low and if there are solids in what is being pumped, the velocity of the water could cause a problem.

A quick internet search can yield not only the mathematical formula to allow you to add this calculation to your arsenal of pump tools, but will also allow you to find the complete Hazen-Williams chart, basically a standard set of numbers rating types of pipe / hose / water conveyance against one another. The lower the number, the poorer the choice / means of conveyance (for example 40 year old cast iron pipe is have and has a very low coefficient and fiberglass pipe is excellent and has a very high coefficient). There are also apps for your phone that put the formula within reach. We are always happy to do the math for you as well.

https://conta.cc/3gK81r2

https://conta.cc/3i9tNpk

https://conta.cc/3x0pRfI

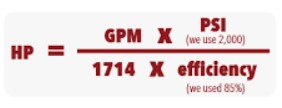

Many of the regular and custom hydraulic power unit inquiries we take start off with a simple question – “I need a hydraulic power unit that will provide X gallons per minute at X psi”. In some cases the customer knows about where they will be with respect to engine size / horsepower, in others they have no idea. So how do you determine how much horsepower you need to deliver a specific flow and pressure? There is a pretty straightforward formula that you can use to answer this question.

Let’s walk through an example. A customer is looking for an HPU that will deliver 15 GPM @ 1800 PSI. The formula below is where we start:

The only thing that is helpful to know ahead of time is the efficiency. Typically at Hydra-Tech Pumps, we will use 85% efficiency for gear and vane pumps, and we use 90% efficiency for variable volume piston pumps. So we will calculate it based on using a gear pump – (15 GPM x 1800 PSI) / (1714 x 85% efficiency) = 27,000 / 1456.9 = 18.53 horsepower required. So now we know that we need a minimum of 18.53 horsepower to produce 15 GPM @ 1800 PSI.

The one thing to keep in mind is that this calculation doesn’t include any kind of parasitic load on the engine like running and alternator or cooling fan – you always want to round up on horsepower when choosing the engine / motor or you might not be able to get to your flow an pressure requirement. In the case of our example above, we would end up using a 23 horsepower (gas or diesel) engine or a 20 horsepower electric motor.

Another thing to keep in mind is this – you can move flow and pressure up and down without changing the horsepower requirement, but you can’t move both up. Below are 3 different requirements (with our example from above in the middle) to illustrate this point – all three can be achieved with the same 18.5 horsepower.

6 GPM @ 4500 PSI

15 GPM @ 1800 PSI

30 GPM @ 900 PSI

Now if you took the greatest flow and pressure requirement from the examples above, 30 GPM @ 4500 PSI, you would need a 100 horsepower unit. We are always here to do the math with you, or for you – let Hydra-Tech Pumps know how we can help you with your next hydraulic power unit requirement!