https://conta.cc/38t3Jyo

https://conta.cc/2AwPyJ2

https://conta.cc/32859dL

It shouldn’t shock you to read that hydraulic fluid is the lifeblood of the hydraulic pump, hydraulic reservoir, and perhaps most importantly the hydraulic motor on your Hydra-Tech submersible dewatering pump. Which hydraulic oil should you choose to fill the reservoir on your new hydraulic power unit? Whether you’re using a 6 horsepower or a 400 horsepower HPU, the choice of hydraulic oil is the same for both (but the volume required to fill it will vary significantly.

For Hydra-Tech’s smallest gas and diesel hydraulic power units of less than 15 horsepower, use Dexron ATF. This hydraulic oil offers a wide temperature range and excellent wear properties.

All hydraulic power units greater than 15 horsepower require AW46 hydraulic fluid in the reservoir and lines. This hydraulic oil has anti-wear additives (AW) and is designed for normal climates – it is 20 weight oil (ISO46). The number 46 is a viscosity value measured in centistokes. In colder climates, we recommend using 10 weight (ISO 32) or AW-32 hydraulic oil.

If you will be operating your HPU around lakes, streams or other environmentally sensitive areas you can fill the unit with environmentally friendly biodegradable hydraulic oil. Most manufacturers offer either a mineral based oil like Chevron CLARITY® or vegetable based oil like Mobil EAL224H.

Just like clean diesel is important for an engine, clean hydraulic oil is important to your hydraulic power unit. Simple steps such as wiping and cleaning quick disconnects with a clean rag can prevent dirt and debris from entering the hydraulic fluid system. Always follow the recommendations in the operator’s manual when it comes to service intervals related to the hydraulic system. In general:

- Change the hydraulic return line filter every 250 hours.

- Change the hydraulic oil every 600 hours (larger models can be 1000 hours).

- Every hydraulic reservoir has a suction strainer with an integral magnet to catch any metal that might get into the system. Any time you are changing the hydraulic oil and the reservoir is empty the suction strainer should be removed, thoroughly cleaned (including removing any metal debris from the magnet), rinsed / cleaned with mineral spirits and properly reinstalled.

These are some general suggestions for our whole hydraulic power unit range – consult your operator’s manual for the exact recommended service intervals for these critical hydraulic system components. Dirt or debris in your hydraulic system can damage or destroy major components like the hydraulic pump on the HPU as well as the hydraulic motor on your submersible pump. Hydraulic oil is the lifeblood of your Hydra-Tech Pumps system – make sure to keep it clean for a long and reliable service life!

https://conta.cc/2SUoSKB

provided some information on Hydra-Tech’s 8000 square foot expansion we are adding to our existing facility. Steel was on the ground and we had some prep work to do to get the site ready. We will be adding on to the truck dock side of our building, since the last update we removed the awning over the patio, demolished the concrete patios on either side of the loading dock, demolished the original entryway and installed a new office entry door on the front of the building. We brought down the parking lot light poles and broke up the bottom of the loading dock (which will be converted into a test tank).

provided some information on Hydra-Tech’s 8000 square foot expansion we are adding to our existing facility. Steel was on the ground and we had some prep work to do to get the site ready. We will be adding on to the truck dock side of our building, since the last update we removed the awning over the patio, demolished the concrete patios on either side of the loading dock, demolished the original entryway and installed a new office entry door on the front of the building. We brought down the parking lot light poles and broke up the bottom of the loading dock (which will be converted into a test tank).Continuing on with the product development theme, and referring back to the last blog post and the phrase “Necessity is the Mother of Invention”, here is another story of how one of our pumps came to be developed.

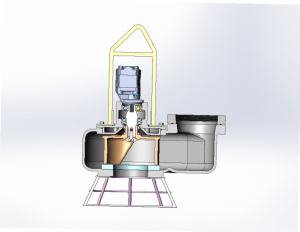

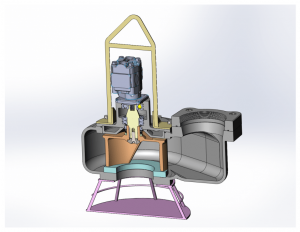

Sometime in early 1990 a customer contacted us looking for a pump to keep dust down on roads that lead in and out of orchards. During dry spells dust would be blown around from vehicle traffic on the dirt roads. The dust would then cover the fruit trees and cause problems. They had a truck with a boom that could extend out 40 feet and wanted to suspend the pump into an irrigation canal that ran alongside the road. They had hydraulics on the truck already, so they could use some of the existing hydraulic power to drive the pump. The pump needed to supply 200 GPM at 100 PSI so they could use a fire nozzle to spray water on the roads as they drove along. Also, the pump could not weigh more than 45 lbs.

Hydra-Tech Pumps had already developed the S3CHL pump (see the last blog post “We Listen Part 1”) but it weighed too much, was more powerful than they needed and required more hydraulic power than was available. The S3CML became a variation that has an aluminum body and requires less hydraulic power to drive it. It was a win/win for the customer and Hydra-Tech Pumps since this pump is now used in many other applications including aviation forest fire fighting (many portable fire fighting applications), barge and cargo ship dewatering, deep well dewatering, tank stripping, irrigation, piling and dock jetting and other high head applications.

The S3CML is available in aluminum and only needs a maximum hydraulic flow of 16 GPM at 3500 PSI for full performance. But like the CHL, what performance you will get! This pump will deliver 460 gallons per minute with no head, but will still deliver 50 GPM @ 380’ of head! Again, just like the CHL, that is a lot of capability from a small pump.

“It pays to listen” and we hear you. Part of our job is to solve problems for customers. Sometimes the solution lies with a combination of existing products, sometimes the solution involves a referral to someone else’s product, and sometimes the solution needs to be developed. Do you have any challenging applications that we can help you solve?