The hydraulic motor. It works hard to convert the flow and pressure of hydraulic oil into work. In the case of Hydra-Tech’s dewatering pumps, this work is pushing a column of water out the discharge and through the hose / piping to its intended destination.

Every hydraulic motor has a pressure inlet and a return outlet (and sometimes a case drain port – but that’s a subject for another time). At Hydra-Tech Pumps we try to stamp P for pressure and R for return on all motors on all pumps built, and on all motors sent as spares. Hydra-Tech Pumps does use some hydraulic motors on our pumps that are bidirectional and the direction in which the impeller spins is determined by which port you connect pressure to. This too is a subject that we will cover in another blog.

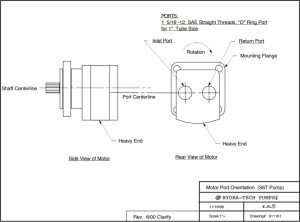

In this post we’re going to focus on unidirectional hydraulic motors which are the majority of what we use on our pumps. These hydraulic motors are not symmetrical, and as you will see below, we reference the heavy side of the motor (as you look at the back of the hydraulic motor). Knowing which port is the pressure inlet and which port is the return port is important, as switching the pressure and return will result in many potential problems from spinning the impeller in the wrong direction, spinning the impeller off of the shaft, and blowing motor lip seals and mechanical seals while dumping lots of hydraulic oil into the body of water where you are pumping.

To help avoid such problems, when you buy a complete system from Hydra-Tech Pumps the quick disconnects / oilfield connections from the pressure connection of the HPU reservoir to the pressure inlet of the pump’s hydraulic motor and return connection from the pump’s hydraulic motor back to the return connection at the HPU oil reservoir are set up to prevent misconnection.

The following statement is true except for the hydraulic motors we use on most axial flow pumps, all 6000 series pumps, slim line pumps, screw pumps, and the S3CML, S3CHL, S4CHL, S8T and S10T. To help yourself deal with a problem in the field, there is a way to tell, on a hydraulic motor used on any Hydra-Tech Pump with a unidirectional hydraulic motor – it has to do with what we refer to as the heavy side of the motor. If you needed to identify the inlet (pressure) and return ports of a motor for any Hydra-Tech Pump (except for exceptions listed above) you would refer to the following drawing:

This drawing is on our website at http://hydra-tech.com/wp-content/uploads/2016/02/Motor-Port-Orientation-.pdf

There are many other helpful technical and troubleshooting references at www.hydra-tech.com that answer common questions and provide support to our customers. Please check out:

Our FAQ page: http://hydra-tech.com/support/faq/

Our Pump and HPU Troubleshooting Guides: http://hydra-tech.com/support/trouble-shooting/